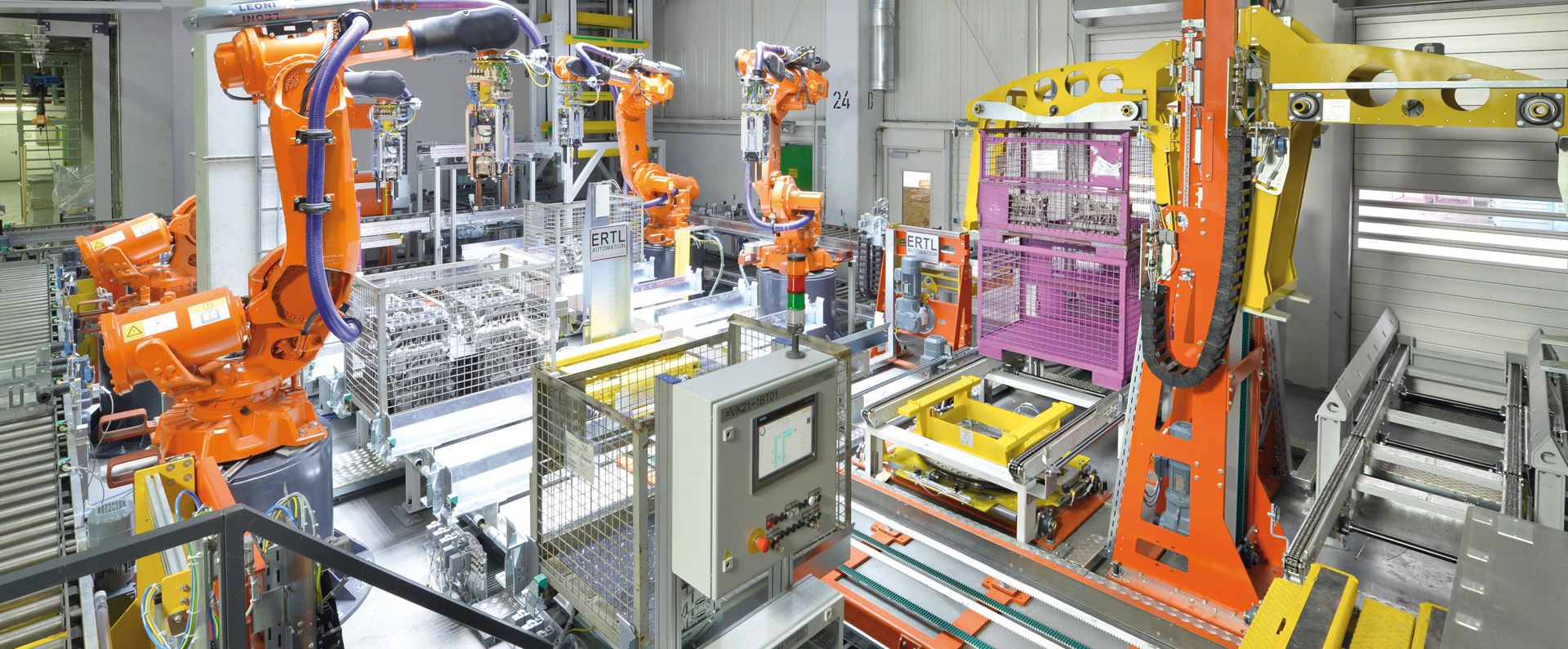

Light metal die cast pouring station

- Automation of individual process steps with high product flexibility in a very confined space via central control

- Sturdy handling units with flexible gripper systems and vacuum technology

- Laser cabin

- Flexible data matrix laser marking of components with robot technology

- Cooling cabin with mist cooling technology

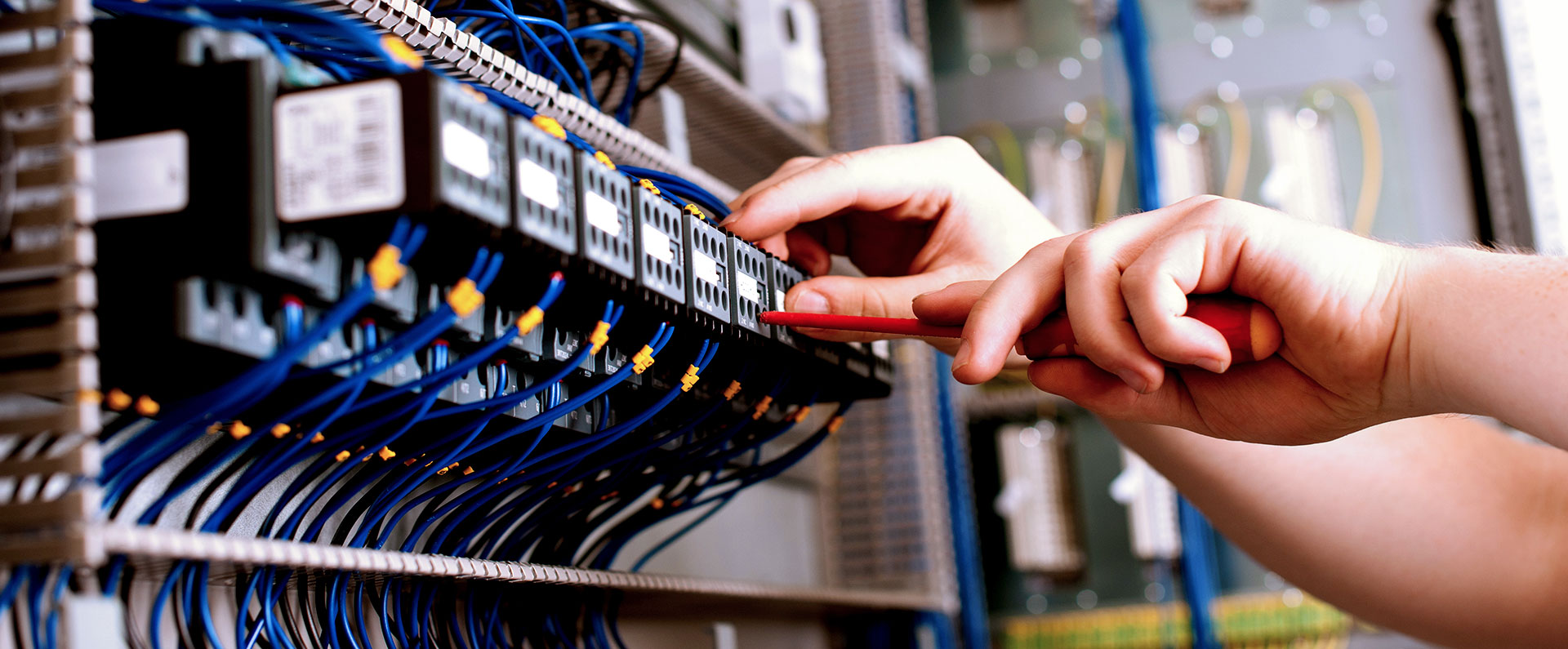

- Control station as central connection to all process partners

- Connection to existing product tracking systems

Video: Light metal die cast pouring station

Brochure for download: