Your advantages:

- Cycle time optimisation compared to conventional solutions (less than 3 sec. per DMC code)

- Smaller code sizes are possible

- Hot marking is possible (to up to 400 degrees)

- Independent of the material

- Laser marking possible in tight spaces

- Easy integration into existing systems

- Simple product change

- Laser-marked DMC / QR code is resistant for further surface treatment

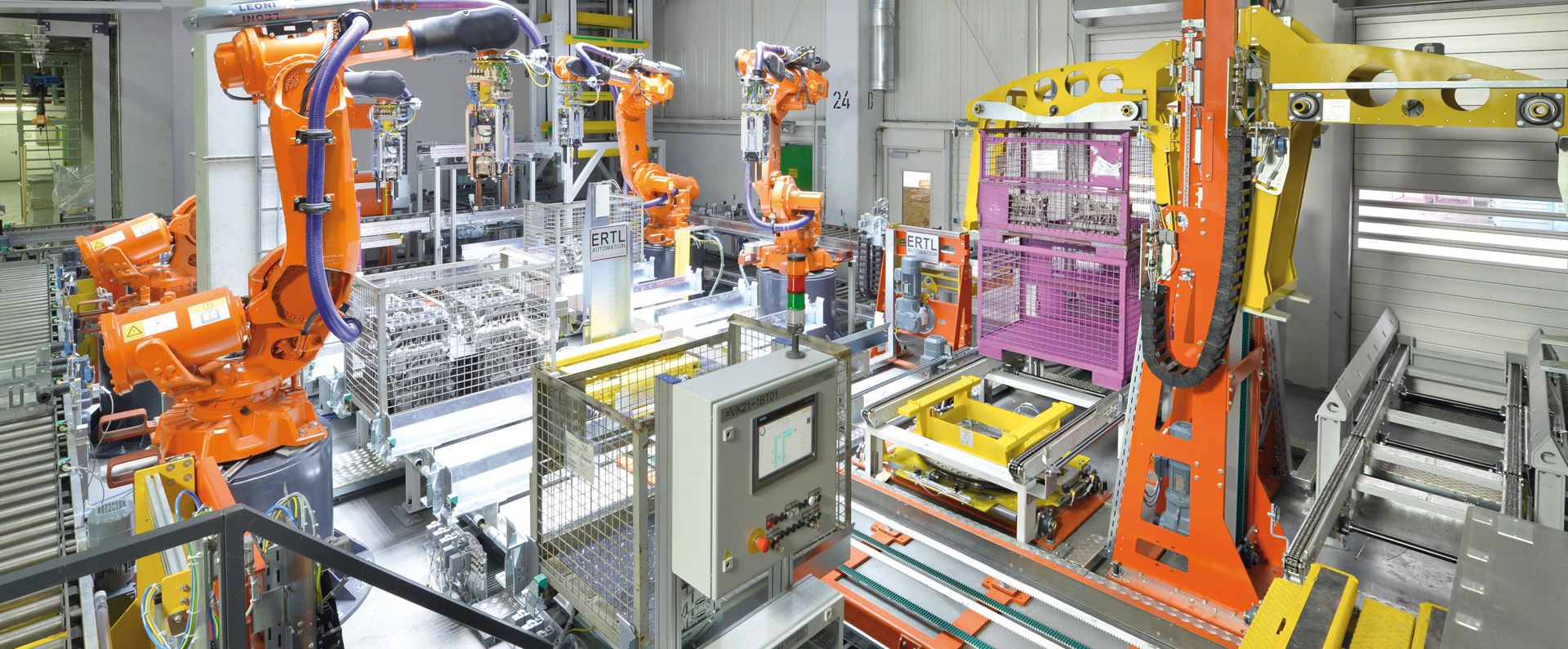

ERTL VARIANT 1 - STATIONARY LASER HEAD

Stationary solution

- The laser head for the DataMatrixCode is in stationary position

- The component is provided via handling robot or via materials handling technology

- The laser head is moved to the component with integrated infeed mechanism

- Intrinsically safe laser head

- No large-scale cabin required

- Incl. protection of the lens against contamination

- Incl. extraction

Your advantages:

- Can be integrated into existing systems

- High flexibility

- Little space requirement

ERTL VARIANT 3 - LIGHTPROOF CABIN

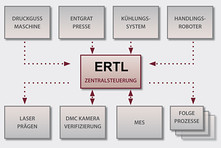

ERTL CENTRAL CONTROL

Our expertise:

- Merging of all data from the different processes

- The DataMatrixCode is used to manage all parameters in the data system of the customer

- The ERTL central control is the superordinated operating and control system

- The control console technology can be used to control all communication and safety systems from one standard interface

- Safe and efficient solution for optimum networking of the systems

- Providing you with a clearly structured workplace

- Individual user-friendly surface

Video: ERTL cast parts laser marking - our exhibit at the EUROGUSS fair

[Translate to Englisch:]

BROCHURE for DOWNLOAD

[Translate to Englisch:] CAST PARTS DMC LASER MARKING

Our innovative traceability solution

![[Translate to Englisch:] Download PDF](/fileadmin/_processed_/f/3/csm_ertl_laserpraegen_broschuere_titel_e_779dac9bae.jpg)